Anisotropy Scanner

When assessing tempered façade glass, anisotropies are a major point of discussion between the glass supplier and the architect or end user. Anisotropies, also known as iridescent areas, consist of dark or colored fields, circles, or stripes. In polarized light, these become visible in direct sunlight from certain viewing angles or with polarizing sunglasses. These undesired effects are caused by differing stress conditions, which mostly stem from the tempering process.

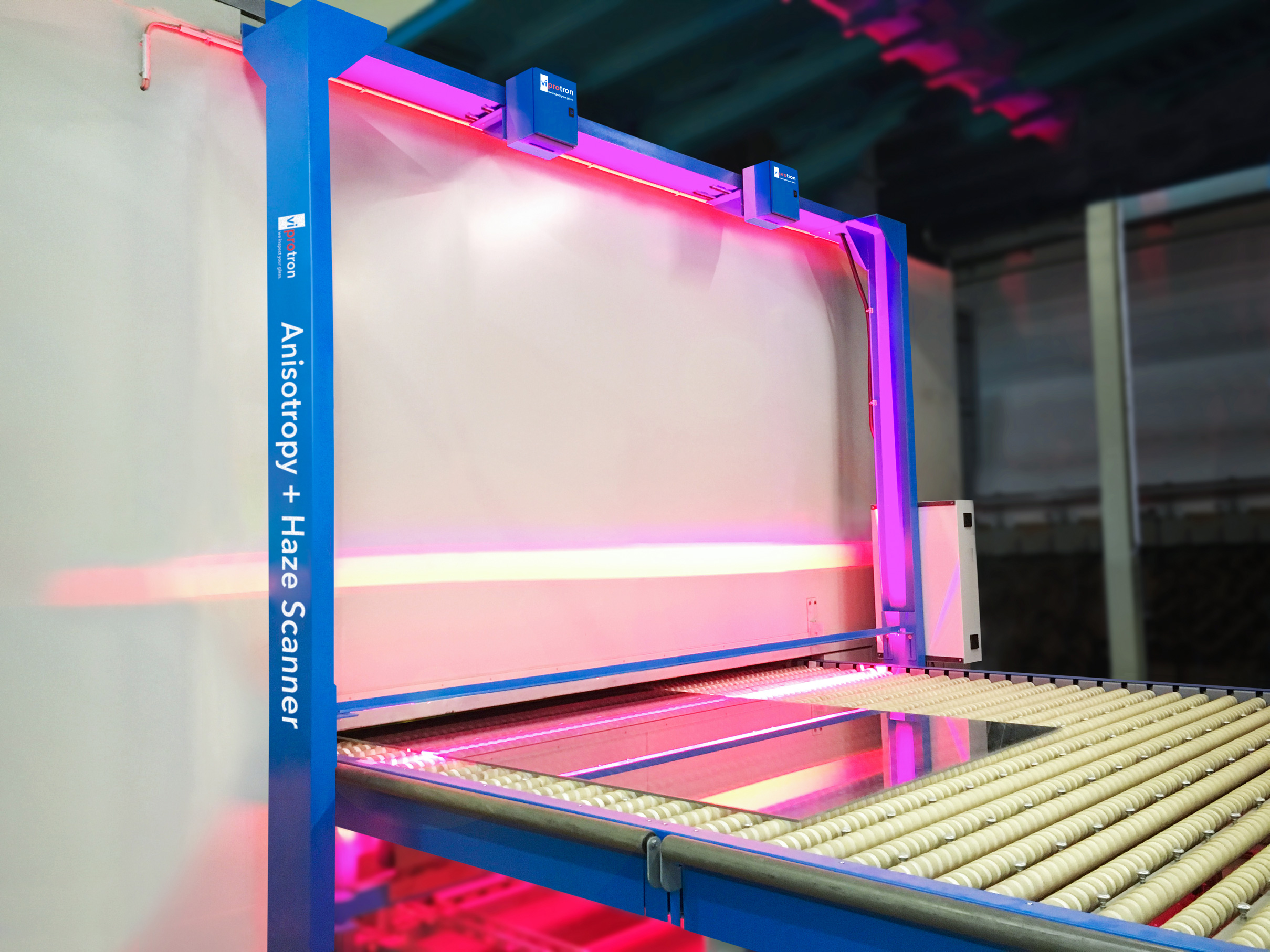

Our Anisotropy Scanner offers the perfect solution to avoid further losses in added value. It measures with polarized light at full production speed and shows for each pane whether the minimum isotropy target value has been reached or to what extent it has been exceeded.

The channels used

The Anisotropy Scanner works in brightfield transmission with polarized light. Optionally, the Anisotropy Scanner can be expanded with a White Haze channel. In combination with the Anisotropy Scanner, the White Haze channel works in the darkfield in transmission. After tempering, this channel reveals areas where damage to the glass surfaces has occurred caused by the furnace. These areas are displayed to the furnace operators for rework, making it possible to polish the defective surface areas before the glass is sent to further processing or to the customer. Unnecessary follow-up costs are a thing of the past!

The testing processes

When testing for anisotropies, it depends on the nanometer. These are units of measurement that are only known in glass from coating technology. It is extremely important that the test is carried out under precisely defined framework conditions. This includes that the polarizing filter used is precisely matched to the wavelength of the incident light. That's why we use exactly one light source, because a certain polarizing filter cannot be calibrated to several wavelengths with low tolerances. The scanner must also automatically determine the light transmission of the glass as it enters the oven and calibrate itself accordingly. That's exactly what we do.

Of course, the visibility thresholds of the anisotropy can be set in Nm in the scanner. The isotropy values can be specified per sheet as average values in Nm or as percentage values in relation to the visibility threshold. If required, you can prove to your clients the production results of each individual pane thanks to the documentation and archiving of the test results.

Is everything too complicated? OK, we look forward to your inquiry and will be happy to help you with your problem of the day.

Areas of application

Behind the tempering furnace

Focus

- Anisotropies

- Optional White Haze

Modularly expandable

- The basis is the brightfield channel with polarized light (according to standards, e.g. DIN SPEC 18198 or ASTM C1901 21)

- Expandable with White Haze channel

Options to

- Improvement of the workflow (e.g. traffic lights, second operating station for furnace operators, etc.)

- Support for automation (connection to lines, ERP or PPS systems)

- Storage and use of data (dashboard, reports, archive)

Technical specifications

Unit height/width |

Up to 3.30 m as standard |

Design |

Horizontal or vertical |

Maximum glass sizes |

3.30 m x 6.00 m - optionally up to 25 m in length |

Glass types that can be tested |

Tempered glass made of float, tinted glass, LowE, sun protection glass, etc. |

Glass thicknesses |

Up to 20 mm – optionally thicker |

Transport speed |

25 m/min |

References

When others were still racking their brains about how to go about determining the anisotropy values, Viprotron launched the first scanner for this purpose in 2016. In 2017 we received the award for the most modern equipment of the year from Glass Magazine (USA).

And of course Viprotron was involved in the development of DIN SPEC 18198 and the US standard ASTM C1901-21. This was the first time that the topic of anisotropies was taken into account in standardization.

Beyond an award, which we can also be a little proud of, or the standardization work, the assessment of our customers with regard to this scanner is much more important as a reference.

We have been working intensively with the Anisotropy Scanner for several years and have been able to benefit enormously from it.

FAQ

-

The standards do not say anything about this. As always with the perception of optical phenomena, there are more sensitive and less sensitive viewers. In practice, threshold values of 50 Nm (sensitive) to 80 Nm (less sensitive) have come up.

-

In principle it doesn't matter. Just be aware that percentages depend on the visibility threshold. For example, the same glass can have an isotropy value of 50% at a threshold of 50 Nm, but will show a value of possibly over 80% at a threshold of 80 Nm. Specifying a percentage value without a threshold value is therefore meaningless. An average value in Nm is a less manipulative representation of isotropy.

-

Both, the average value and the percentage value always give an evaluation of the entire glass surface. But the Anisotropy Scanner is of course able to evaluate individual, particularly affected areas separately. A glass that is otherwise good in terms of the average rating, can still be outside the desired specification due to a very noticeable anisotropy on a partial area.

-

If a glass is glazed in a frame system, the edges that are particularly susceptible to anisotropy are covered by the frame. Of course, it can then be set in the recipe at what distance from the edge of the glass the evaluation is omitted. Incidentally, the same applies to drilling holes.

Factsheet Anisotropy Scanner

The most important information and advantages of the Anisotropy Scanner at a glance.

Factsheet Inspektions Systeme

The advantages of our scanner systems at a glance. Because the higher quality of your glasses makes the difference.

Contact

You would like to coordinate a project with us or have questions about products and services? Then simply call us or send us an e-mail. We are looking forward to your message!

Contact details

Viprotron GmbH

Ostendstraße 17

64319 Pfungstadt

Germany

- Phone number

- +49 6157 986 380

- info@viprotron.de

Viprotron North America Inc.

7501 S. Jackson Gap Way

Aurora CO 80016 – USA

- Phone number

- +1 313 384 3855

- ric.schmidt@viprotron.com